Additive Manufacturing: A Departure from Traditional Methods

For centuries, manufacturing relied on subtractive processes. Think of sculpting: you start with a large block of material and remove material until you achieve the desired shape. Additive manufacturing, or AM, flips this script. Instead of subtracting, it adds material layer upon layer, building a three-dimensional object from a digital design. This fundamental shift opens doors to previously unimaginable design possibilities and manufacturing efficiencies.

The Core Principles of Additive Manufacturing

At the heart of AM is the ability to create complex geometries with intricate details that would be impossible or prohibitively expensive to produce using traditional methods. This is achieved by using computer-aided design (CAD) software to create a digital model of the object. This model is then sliced into numerous cross-sections, which serve as instructions for the AM machine. The machine then deposits material layer by layer, precisely following the digital blueprint. The process can be likened to building a three-dimensional structure with incredibly thin layers of “bricks”.

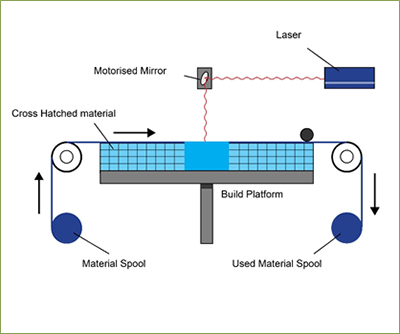

Diverse AM Technologies: A Range of Applications

The term “additive manufacturing” encompasses a wide range of technologies, each with its own strengths and weaknesses. Some popular methods include Stereolithography (SLA), which uses a laser to cure liquid resin; Selective Laser Melting (SLM), which fuses powdered metal using a laser; Fused Deposition Modeling (FDM), which extrudes molten plastic filament; and Binder Jetting, which uses a binder to bind powder particles together. This diversity allows AM to be applied across various sectors, from aerospace and medical devices to consumer products and art.

Advantages of Additive Manufacturing: Speed, Efficiency, and Innovation

One of the biggest advantages of AM is its ability to rapidly prototype designs. Instead of waiting weeks or months for tooling and production, designers can create functional prototypes in a matter of days. This accelerates the design iteration process, leading to faster product development cycles. Furthermore, AM excels in producing highly customized products, allowing for mass personalization without incurring significant additional costs. Complex internal structures and lightweight designs, often impossible with traditional methods, become readily achievable with AM, leading to innovative solutions in various fields.

Addressing the Limitations of Additive Manufacturing: Material Choices and Scalability

While AM offers numerous benefits, it’s not without its limitations. The range of materials that can be used in AM is still expanding, but it doesn’t yet match the breadth available in traditional manufacturing. Furthermore, for high-volume production, AM may not always be the most cost-effective solution compared to established techniques like injection molding. The speed at which a single AM machine can produce parts can also be a limiting factor compared to the high throughput of conventional manufacturing lines. However, ongoing advancements in technology continue to address these challenges.

The Future of Additive Manufacturing: Continued Growth and Integration

Despite its current limitations, the future of additive manufacturing looks bright. Ongoing research and development are constantly expanding the range of materials, improving the speed and precision of AM processes, and reducing production costs. We can expect to see greater integration of AM into existing manufacturing workflows, enabling hybrid manufacturing processes that combine the strengths of both additive and subtractive techniques. This synergistic approach will further optimize production efficiency and unlock even more innovative product designs.

Additive Manufacturing’s Impact Across Industries: Revolutionizing Design and Production

The impact of additive manufacturing is already being felt across a wide range of industries. In healthcare, AM is enabling the creation of personalized medical implants and prosthetics. In aerospace, it is facilitating the production of lightweight, high-strength components. The automotive industry is leveraging AM to create complex parts and customized vehicle components. The possibilities are truly vast and continue to evolve as the technology matures and expands its applications.

Beyond the Technology: Economic and Societal Impacts

The adoption of additive manufacturing is not just a technological shift; it represents a significant change in how we design, produce, and distribute goods. It has the potential to revolutionize supply chains, enabling localized manufacturing and reducing reliance on globalized production networks. Furthermore, it can foster entrepreneurship and innovation by lowering the barriers to entry for small and medium-sized enterprises (SMEs) that want to engage in manufacturing. The economic and societal implications of AM are far-reaching and continue to unfold.

Understanding the Terminology: Common AM Jargon

Navigating the world of additive manufacturing often involves understanding a specialized vocabulary. Terms like “build plate,” “infill,” “support structures,” and “post-processing” are commonly used. Familiarizing oneself with this terminology is key to understanding the capabilities and limitations of different AM technologies. Many resources are available online to help demystify this technical jargon and empower users to make informed decisions about AM applications. Read more about additive manufacturing definition.